Delivery time: Stock/ 7-30 days for customized machine

MOQ: 1 set

Payment terms: TT, LC, Paypal

Shipping way: Express, by Sea, by air

Nearest sea port: Shanghai sea port

Supply capability: 200 sets/month

Packing: Wooden box

0

0Delivery time: Stock/ 7-30 days for customized machine

MOQ: 1 set

Payment terms: TT, LC, Paypal

Shipping way: Express, by Sea, by air

Nearest sea port: Shanghai sea port

Supply capability: 200 sets/month

Packing: Wooden box

▶ Machine Characteristics

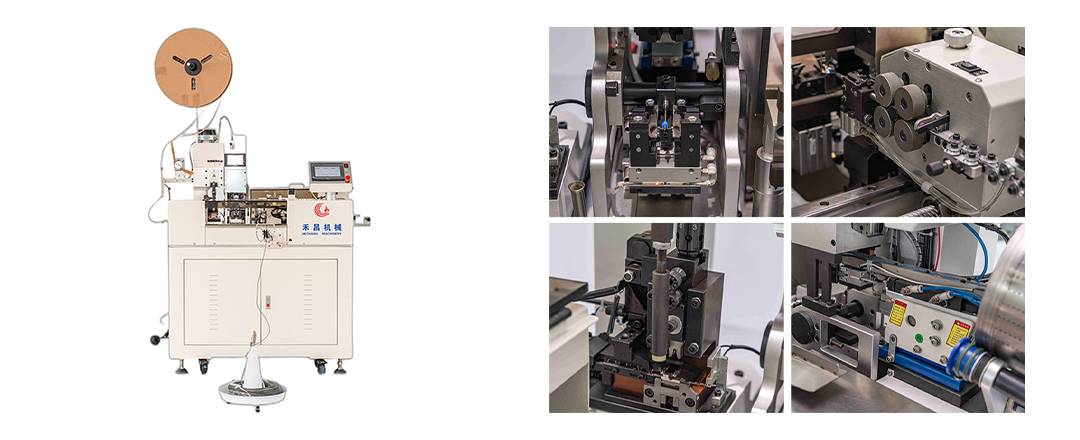

1. The machine adopts imported original parts to complete the cutting of wires, stripping, wearing waterproof plugs, terminal crimping, twisting, etc., with simple operation, stable performance and labor saving.

2. The tightness of the crimping roller and the depth of the cutting knife are adjusted by the fine-tuning knob, which is simple and fast.

3. The whole stripping length is set directly by the touch screen menu panel. The best features are: fast technical performance adjustment, short adjustment time, simple and convenient operation.

4. The crimping machine itself is constructed with nodular cast iron, providing strong rigidity and a stable crimping height. It can be equipped with a crimping force monitor that continuously monitors the crimping force curve during each crimping process. If the crimping force deviates from normal values, the machine will automatically trigger an alarm and stop the operation. Furthermore, a CCD visual inspection system or a laser profiler can be chosen to inspect the insertion position of the waterproof plug and the appearance of the terminal crimping.

5.The machine is designed with flexibility in mind, allowing it to process a variety of different products. When replacing the waterproof plug, it is only necessary to replace the corresponding track fixture, enabling quick product switching within a few minutes. The program memory function stores the processing parameters of different products in a database. When switching products, the operator can easily retrieve the corresponding processing parameters with a single key press, saving time on debugging and setup. Additionally, the machine can be equipped with a computer industrial control system that supports MES (Manufacturing Execution System) connection. It has a built-in network interface, enabling connection to the MES system through a local area network. This connectivity allows for remote reading or setting of parameters, as well as remote production tasks and other functions.

▶ Watch Video

▶ Machine Specification

| Model | HC-10+FS |

| Power | AC220V/50HZ |

| Function | Wire cutting, one side stripping, two ends stripping, one end crimping, one end twisting wire, seal insertion |

| Processing Capacity | 1500Pcs/hour (within 200mm) |

| Applicable wire range | AWG#26-AWG#14 (0.2-2.5mm2) |

| cutting length | 50mm-9999mm |

| Cut-off precision | Tolerance: 1 mm+cutting length *0.2% |

| Stripping length | Front end: 1.5 mm--10 mm, Rear end:3-15mm |

| Twisting length | 3-15mm |

| Press Capacity | 1500KG |

| Air pressure | 0.5-0.65mpa (use clean dry air) |

| Detecting devices | Wire exists or not, crimping no good |

| Measurement | L950*W1200*H1550mm |

| Weight | 480kg |

| Can be installed and configured | CCD visual detection, pressure monitoring |

▶ Application

▶ Company Advantage

With a professional team of R & D experts, advanced processing technology, and a firm commitment to customer satisfaction, HeChang Intelligence strives to provide first-class wire harness solutions.

When it comes to service, we assure you that during the guarantee period, should any issues arise with our machines, please notify us immediately if the machine is not functioning correctly. Providing pictures or videos that clearly depict the problem will be helpful. We are committed to resolving any problems within 24 hours, and if necessary, our technical personnel will provide on-site assistance.

Changzhou Hechang Intelligent Technology Co., Ltd. is dedicated to delivering high-quality wire harness processing equipment, exceptional service, and ensuring utmost customer satisfaction.

▶ Our Honor

Our equipment has obtained many patent certificates and certifications. With a dedicated team of R&D experts, advanced processing technology, and a strong commitment to customer satisfaction, we strive to provide top-quality solutions.

▶ FAQ

Q: What are the wearing parts? A: Blade and belt. More spare parts info, please contact us.

Q: Operation and user manual? A: English and Chinese optional.

Q: How long is the warranty period?A: 1year, all belts and blades without of the warranty.

Q: What after sales service do you provide?A: Technicians online support, video technical support within 24 hours.

If you need local service please check with Hechang Machinery. Generally require additional charges.